For woodworkers as well as DIY enthusiasts, the choice of materials can make or break the outcome of a project. Solid wood remains a timeless classic engineered wood panels, such as MDF boards (Medium Density Fiberboard), melamine sheets, and particle board are a compelling alternative. Knowing the distinct properties and functions of each is essential to producing stunning and efficient results.

MDF Board: The Champion of Softness and Versatility

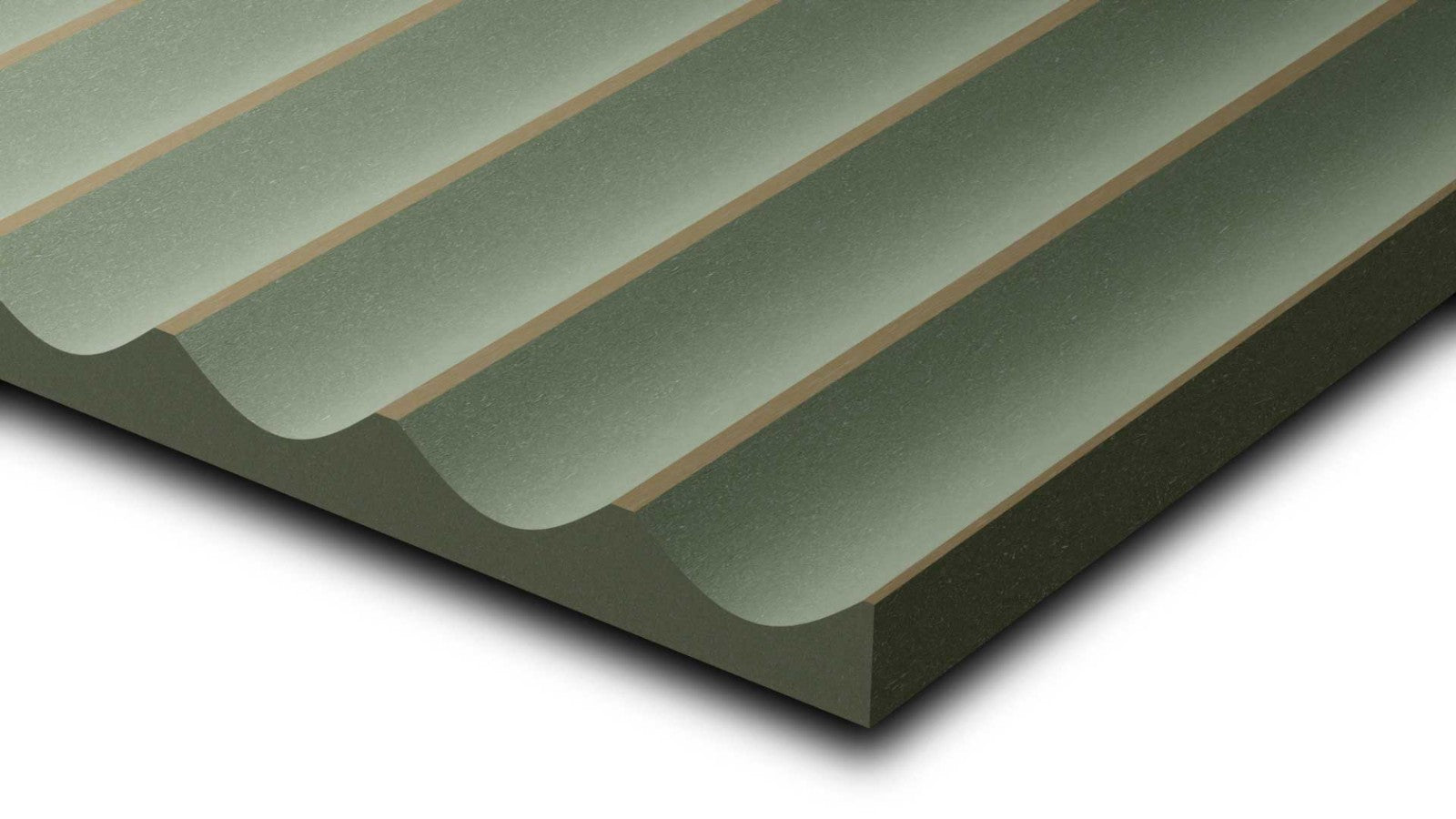

MDF boards have become a staple in woodworking shops all over the world. The smooth surface of MDF boards is easy to work with and will accept paint, stain and other veneers. MDF boards are more solid than solid wood, and are therefore less prone to warp, or crack. This consistency allows them to be used for complex carvings, moldings, as well as for the creation of intricate architectural designs.

The benefits of using MDF Boards:

Professionally-looking surfaces are created by the smooth surface, which allows for flawless paint and veneer applications.

The ability to work: MDF boards are easy to cut, drill, and rout, which makes them perfect for intricate designs and complex projects.

MDF Boards are sturdy and long-lasting: MDF boards of high quality are built to withstand everyday water and wear despite their appearance.

The versatility of MDF boards ranges from making furniture to building cabinets and even creating architectural elements, MDF boards have a variety of uses.

Melamine Sheets Durability is a must

Melamine sheets add a decorative finish to MDF boards. The sheets are created using an extremely thin layer of melamine resin that is bonded to MDF creating a durable and attractive surface. Melamine surfaces are available in a wide range of colors and patterns.

Melamine Sheets are a fantastic alternative to traditional sheets.

It is resistant to stain and scratch marks. Melamine coating offers exceptional resistance to scratches, stains, and fading, making ideal for areas that are heavily used like bathrooms and kitchens.

Easy Maintenance: Melamine sheets require minimal upkeep. Simple wipe-downs with a wet cloth can keep them looking nice.

Cost-effective Option: Melamine Sheets like solid hardwood but have greater aesthetic value and are a cost-effective alternative but still retain a classy look.

Melamine sheets are flexible and can be used in a wide range of projects, including kitchen cabinets and countertops as well as furniture and wall panels.

Budget-Friendly Particle Board

Although it isn’t as popular as MDF or melamine board is a good option for projects that prioritize quality over appearance. It is made of wood particles compressed and resin-bonded, particle board gives you a great level of durability and strength.

Understanding Particle Board:

Cost-effective: Particle board is the least expensive choice of the three.

Application Limitations: Particle board’s rougher surface and low humidity resistance make it ideal for use in areas where aesthetics is not the primary issue. Examples include interior furniture elements and subflooring.

Highly prone to moisture: Particle board can swell and lose its structural integrity when exposed moisture. When working in humid environments it’s essential to select those that are moisture-resistant.

Selecting the right engineered wood panel

Selecting the ideal engineered wood panel is contingent on your project’s specific needs and requirements. Here’s a quick overview that will assist you in making a choice:

For smooth and flawless finishes, intricate designs, and general flexibility: MDF boards are the most obvious choice.

Melamine sheets provide the greatest combination of toughness, scratch resistance and pre-finished surface.

For budget-conscious projects where structural integrity is a major concern: Particle board can be a viable choice.

The Future of Woodworking: Embracing Engineered Wood Options

MDF boards, melamine sheets, and particle board present an array of options for woodworkers and DIY enthusiasts. Their low cost, versatility, and consistent performance makes them an essential part of any project toolbox. Engineered wood solutions will continue to develop as technology progresses, expanding the possibilities of creativity for future woodworking.